- Home

- About Us

- Products

- News

- Video

- Contact

- Send Inquiry

Search

- Home

- About Us

- Products

- News

- Video

- Contact

- Send Inquiry

In today’s increasingly connected and mobile-driven world, high-brightness sunlight-readable LCD screens are essential for applications ranging from outdoor kiosks and military equipment to industrial control panels and public transportation systems. These displays must perform reliably under direct sunlight—often exceeding 10,000 lux—and maintain clarity, contrast, and color accuracy in challenging lighting conditions. The display ratio of 16:9 is now the industry standard for most modern LCDs due to its compatibility with HD, Full HD, and 4K video content, as well as its optimal balance between width and height for both horizontal and vertical viewing.

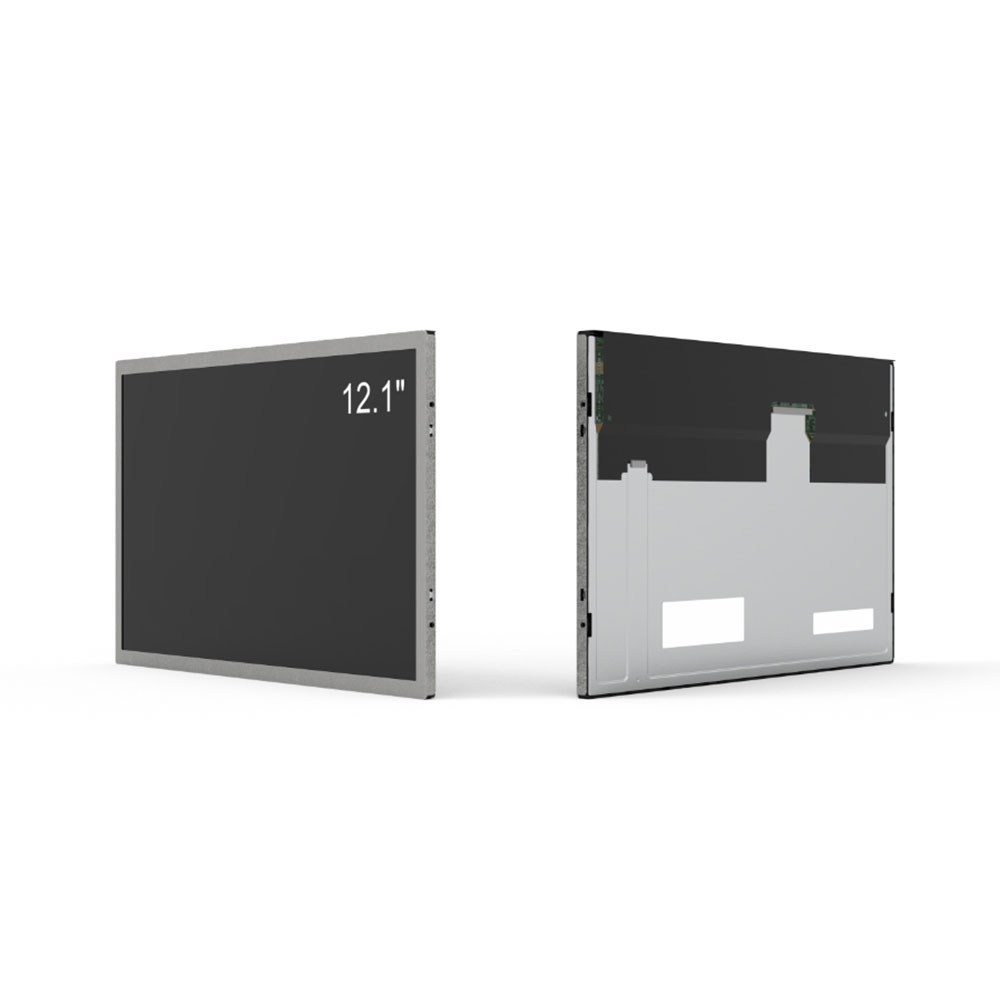

Manufacturers offer a wide range of sizes—from compact 10.1-inch units ideal for handheld devices and embedded systems to massive 110-inch displays used in command centers and digital signage. Each size presents unique engineering challenges. For example, smaller displays (10.1”–21.5”) benefit from advanced LED backlighting, anti-reflective coatings, and high-contrast IPS or TN panels that ensure visibility even at extreme angles. Larger formats (23.8”–110”) often use local dimming technology, edge-lit or full-array backlights, and ruggedized aluminum frames to withstand environmental stressors such as temperature extremes, vibration, and humidity.

A key metric in evaluating these displays is brightness, typically measured in nits. While consumer-grade LCDs may reach 300–500 nits, sunlight-readable models are designed to exceed 3,000 nits—some reaching up to 7,000 nits for military-grade applications. This performance is achieved through innovations like high-efficiency LED arrays, precision optical films, and intelligent brightness control algorithms that adapt based on ambient light sensors. Additionally, manufacturers integrate features such as wide viewing angles (>170°), high refresh rates (≥60Hz), and touch compatibility (resistive or capacitive) to support diverse user interactions.

Industry case studies confirm the value of these technologies. In a recent deployment by a major logistics company, 27-inch sunlight-readable LCDs installed in warehouse terminals improved operator efficiency by reducing input errors caused by glare. Similarly, an aerospace manufacturer adopted 15.6-inch displays with 5,000-nit brightness for cockpit monitoring systems, significantly enhancing pilot situational awareness during daylight operations.

Standards such as MIL-STD-810G for ruggedization and IEC 60068 for environmental testing guide the design process. Compliance ensures reliability in real-world conditions, including shock, vibration, dust ingress (IP65), and thermal cycling (-20°C to +70°C). With global demand rising—from smart cities to autonomous vehicles—manufacturers are investing in scalable production lines, modular designs, and software-defined interfaces to meet evolving needs.

Ultimately, choosing the right sunlight-readable LCD involves balancing size, brightness, durability, and application-specific requirements. Whether it's a 10.1-inch unit for field service or a 98-inch screen for public information displays, the correct selection can make the difference between operational success and failure under harsh environmental conditions.